Grasys IT

Integrated information technology solutions

for industry

Integrated information technology solutions

for industry

Main business lines of Grasys IT

- Development of software for computers and industrial controllers, automated control systems

- Design of computer systems and data transmission systems

- Activities to support computer, automated and security systems

- Activities related to the use of computer technology, industrial controllers, control systems and information technology

- Activities to create and use databases and information resources

- Consulting and performance of work in the field of computer and information technologies (data acquisition systems, automated control systems, low-current networks)

Grasys IT carries out the entire cycle of creating automated control systems (ACS) from pre-design inspection of the facility to commissioning

- Pre-project survey

-

Development of technical specifications

- Software development

- Development of design, working and operational documentation

- Passing the examination and approval with supervisory authorities

- Carrying out installation supervision work

- Carrying out commissioning work

- Conducting training for customer personnel

- Commissioning of the system

- Post-sales support and service

Competencies of Grasys IT

Development of structure, control algorithm, software development for microprocessor protection systems and substation automation

- We carry out the development of structure, control algorithms, programming of logical controllers of microprocessor protection systems and automation of substations 6 (10 kV) performing the functions: control, protection, blocking from abnormal operating conditions of the power supply system of industrial enterprises.

- We develop algorithms, software, automation for distribution substations 6-110 kV.

- We provide the customer’s operator with a clear display of the required parameters, maintaining event logs, remote control, and monitoring.

Development of structure, control algorithm, software development for emergency transfer systems

Development of a structure, control algorithm and programming of logical controllers for emergency power reserve input systems with automated start-up of generator sets for the first special category of power supply reliability for especially critical consumers. Development and implementation of a control algorithm for “unloading” excess consumers of industrial enterprises when powered by a generator set.

Development of structure and algorithms for technological protection of compressor equipment

Implementation of the structure and algorithm of technological protections as part of a local control system for compressor equipment. Integration with a microprocessor control system for a 6 kV (10 kV) power supply source.

Design of automated control and metering systems for electricity

Design of automated control and metering systems for electricity with the following functionality: automatic collection of commercial metering data for electricity consumption (supply) for each metering point (group) at specified commercial intervals. Storing power quality parameters in a database. Providing multi-tariff metering of electricity consumption (supply).

Design of automated dispatch control systems for power supply

Design of automated dispatch control systems for power supply of industrial enterprises (ASDUE) with the following system functionality: determination of the current states of switching elements; measurement of current values of technological parameters (currents, voltages, active and reactive powers, etc.); enabling and disabling controlled objects; archiving of all events and measurements, maintaining a database.

Development of design, working and construction documentation for automated process control systems

Development of working and design documentation for automated control systems based on a set of regulatory documents ESKD, ESPD. When designing, leading domestic and foreign equipment manufacturers are used. Modern design tools (AUTOCad, EPLAN P8) are used to develop documentation.

Design of automated process control systems with increased requirements for fault tolerance

Design of automated process control systems with increased requirements for fault tolerance. Development of control cabinets, telecommunication cabinets, server cabinets (for process control systems), supply of automated operator stations (AWP) for monitoring and managing technological parameters and the facility.

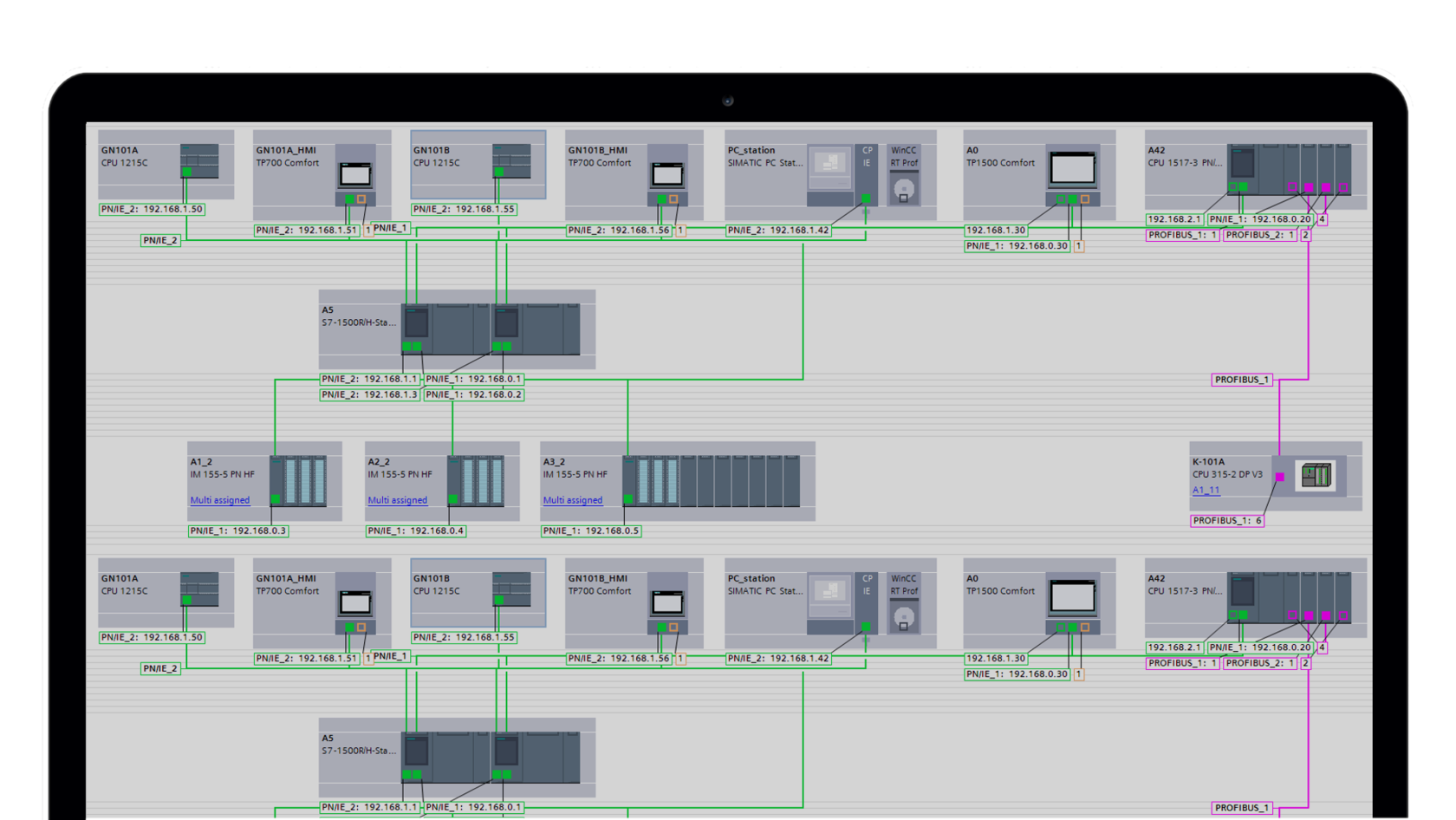

Design of computer systems and data transmission systems

Design of computer systems and data transmission systems using Ethernet technology (including fiber-optic communication lines). This technology provides connection of personal computers, industrial logic controllers, industrial machines, control and security systems, video surveillance, access control and management systems.

Development of monitoring and control systems for medical oxygen generators

Development of monitoring and control systems for medical oxygen generators and concentrators built on their basis (See attached certificates), which were supplied as part of the re-equipment of medical institutions.

Components used

The implemented automation systems are based on the use of modern, highly reliable microprocessor monitoring and control tools produced by trusted domestic and foreign manufacturers, such as:

Own development and production

ACS equipment produced by Grasys IT

- Product qualityThe quality management system is confirmed

by certificates ISO 9001:2015 - FlexibilityPossibility of production based on required components

Completed projects

Grasys IT has successfully implemented more than 1,500 projects in the field of automation, including large-scale EPC projects.

EPC project

NITROGEN PRODUCTION AND

AIR COMPRESSION COMPLEX

EPC project

NITROGEN PRODUCTION COMPLEX

EPC project

GAS COMPRESSION AND TREATMENT COMPLEX

EPC project

NATURAL GAS TREATMENT COMPLEX

EPC project

ASSOCIATED PETROLEUM GAS TREATMENT COMPLEX

Why choose us?

- ExperienceMore than 20 years of experience in successful implementing projects in the field of automation and energy.

- CompetenciesDevelopment, design and implementation of systems of any scale and level of complexity.

- Effective solutionsAn in-depth study of the goals and objectives of the project allows us to develop and implement the most effective solutions.

Contact us

By clicking on the button, you agree to the terms of personal data processing

Contacts

© 2025 Grasys IT LLC. All rights reserved.

Privacy Policy..

Legal information

Results of a special assessment of working conditions (SOUT) at workplaces at Grasys IT LLC

Privacy Policy..

Legal information

Results of a special assessment of working conditions (SOUT) at workplaces at Grasys IT LLC